Vacuum Packaging

Vacuum Packaging

Vacuum Packaging for low-hydrogen, low-alloy-steel and Stainless-Steel groups Welding Electrodes

ELKADESIA Engineering industries(Bohler Egypt) is pleased to announce the launching of its 2 kg vacuum pack options in order to better serve the needs of different industries where low hydrogen content and extra protection are required.

ELKADESIA vacuum pack not only eliminates the moisture pick up but also excludes the re-baking procedures as well as reducing the risk of hydrogen embrittlement and delayed cracking. It also helps to avoid additional cost of storage, handling, re-drying or baking.

ELKADESIA vacuum pack provides an air-tight package to keep moisture from damaging the coating flux on stick electrodes.

Using a strong aluminum foil made of multi-layered, the new ELKADESIA Welding packaging offers maximum safety against loss of vacuum.

With the vacuum in place, electrodes are ready to use. The packs can be stocked in any store where the packaging cannot get damaged.

Protect Your Electrode from Humidity

Low-hydrogen, low-alloy-steel and Stainless-Steel groups, the humidity captured in the flux of electrode turn in to water vapor in the welding bead. Water vapor shrink in the weld bead and porosities occur. These porosities decrease the mechanical properties of the weld metal and the beads become unstable.

Due to these negative effects of the humidity, electrodes must be protected in the best way. ELKADESIA is proud to advise the Vacuum Packages which do not get humid if the package is not open and which has 12 hour critical humidity level guarantee after the package is open.

Cost Saving

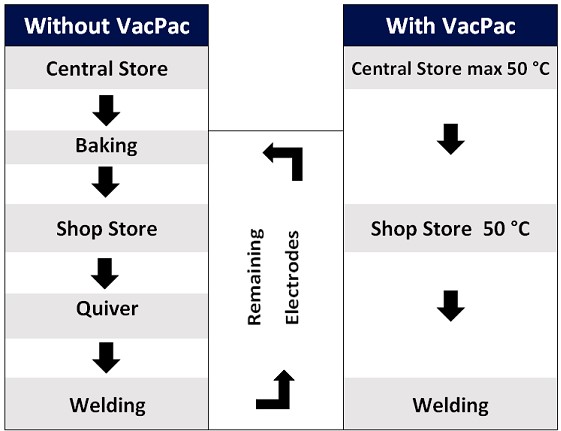

Cost savings through simplified storage and handling

The prevention of hydrogen induced cracking in thick structural steels or porosity in low-alloy-steel and stainless, by controlling the moisture re-absorption in the coating of low hydrogen electrodes can be very costly. In demanding applications, such as offshore fabrication,

the cost of climate controlled storage and handling and the associated administrations are often calculated to exceed the cost of the consumables itself.With electrodes from ELKADESIA vacuum packaging, these costs are completely avoided.

Not need to Re-Baking, Holding Ovens, or Quivers

Welding electrodes from Vacuum Pack can be used straight from the package without the need to re-bake them and store them temporarily in holding ovens and quivers.

The laminated, multi-layer aluminum foil is vacuum-sealed around an inner box and effectively protects the electrodes against moisture re-absorption from the air. Protected by a cardboard outer box, they have unlimited shelf life and do not require special warehouse conditions, provided they are handled with care and the foil is not damaged. Upon opening, Fresh and dry electrodes are guaranteed when the vacuum is confirmed.

Safe & Benefits

Safe Welding After Opening

ELKADESIA welding electrodes in Vacuum Pack are low moisture absorption (LMA) types with a coating that only slowly re-absorbs moisture from the air. The safe exposure time is 12 hours* after opening the Vacuum Pack with the foil left in place.

For optimal security, it is recommended to take out only one electrode at a time. The Vacuum Pack sizes available are 2.5 mm, 3.25mm, 4.0 and 5.0mm, Electrodes exposed beyond above limits must be re-baked.

Vacuum Pack provides security and makes the welder’s life easier; in offshore and pressure vessel fabrication, the petrochemical industry, the food processing industry and other applications where the prevention of cold cracking or porosity is crucial.

Vacuum Packaging benefits

- No re-baking, no holding ovens, no quivers.

- Safe welding after opening.

- Cost savings through simplified storage and handling.

- Reduced risk of hydrogen cracking or porosity.

- Easier for welders to carry.

A word about kadesia

El-Kadesia Engineering Industries is the Egyptian market leader in manufacturing of Shielded Metal Arc Welding (SMAW) since 1985 by its founder Mr. Mohamed Naguib Gwefel;

El-Kadesia Engineering Industries is the Egyptian market leader in manufacturing of Shielded Metal Arc Welding (SMAW) since 1985 by its founder Mr. Mohamed Naguib Gwefel;

is the Egyptian market leader in welding electrodes with more than 38 years of accumulated experience in the industry.

El-Kadesia was established in 1985 by its founder Mr. Naguib Gwefel ........

Subscribe

Subscribe to our newsletter to receive the latest news and updates on Kadesiawelding.com